After the COVID break, Studio Scano recently presented a new technical paper titled “Impact of General and Local Metal Loss on the API 579-1 Creep Residual Life” at the ASME Pressure Vessels and Piping Conference (PVP) in Las Vegas (Nevada).

Creep and metal loss are typical, concurrent damage mechanisms of high-temperature pressure components. Both phenomena are time-dependent and interact with one another: the reduction of wall thickness (global or local) impacts on the stress field and the creep accumulated damage changes accordingly. Despite this fact, no direct guidance is given in Fitness-For-Service standards, like API 579-1, to address these mechanisms simultaneously and the common approach is to run the creep analysis with minimum-thickness conditions, i.e., fully accounting for the future corrosion allowance. This is the simplest way and the most conservative, but how conservative?

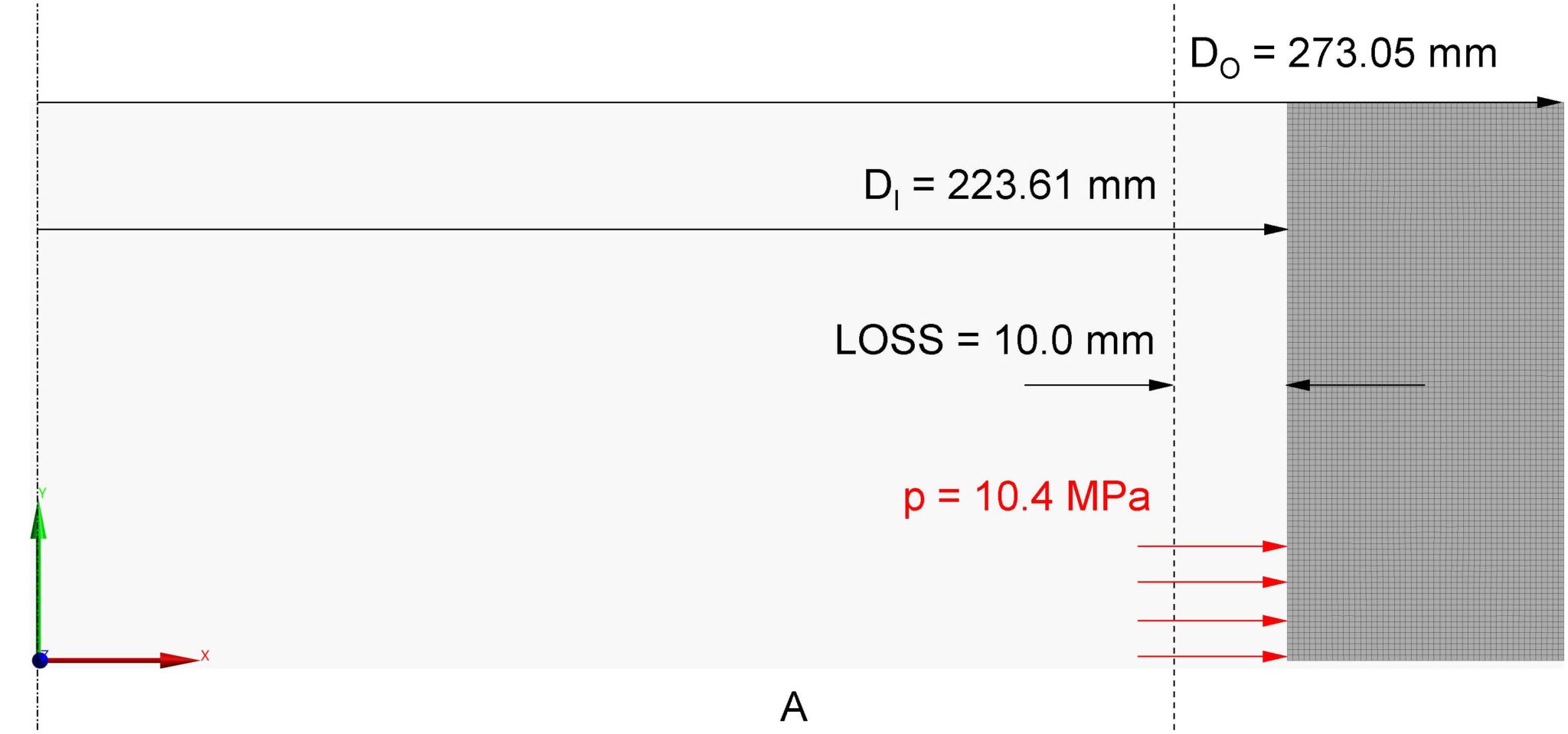

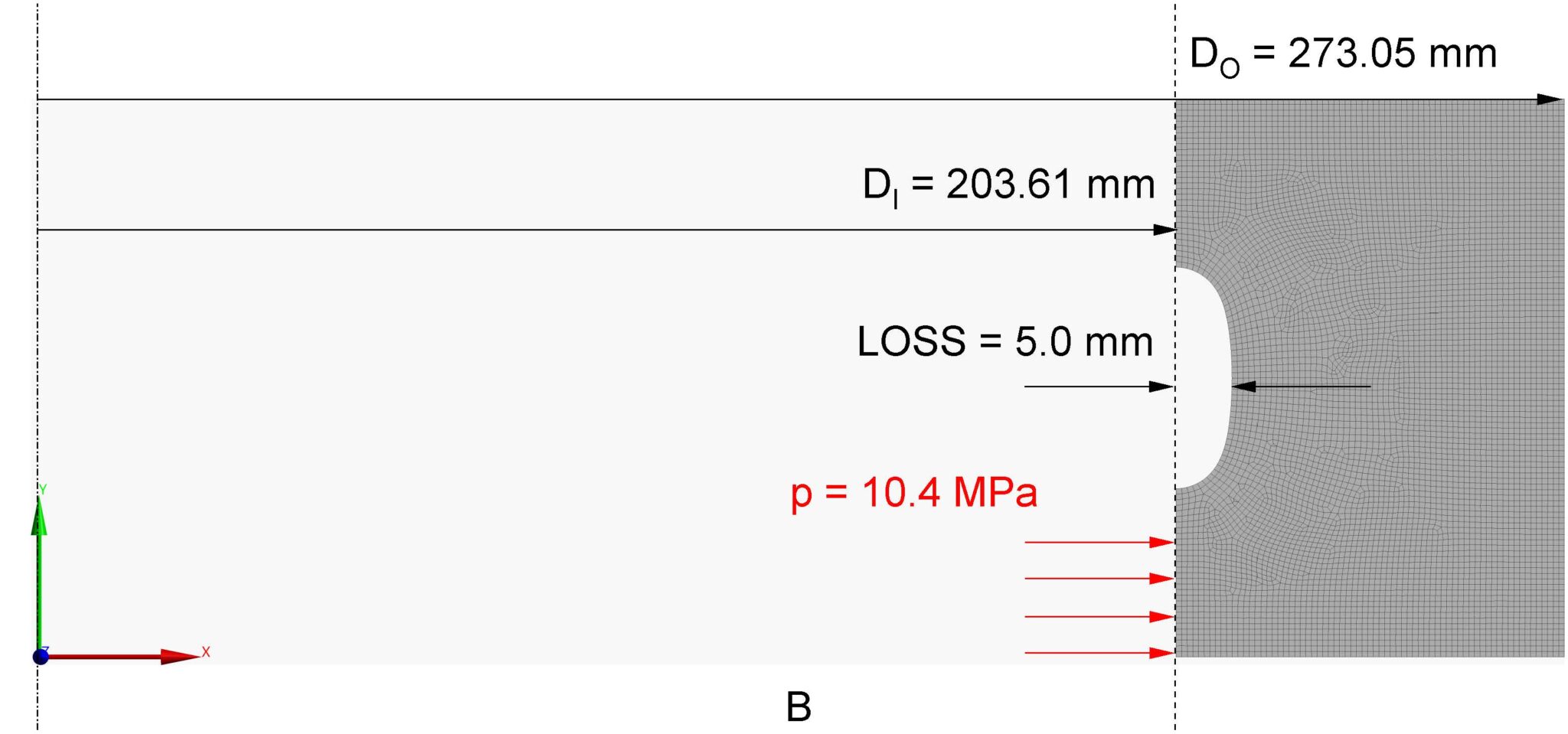

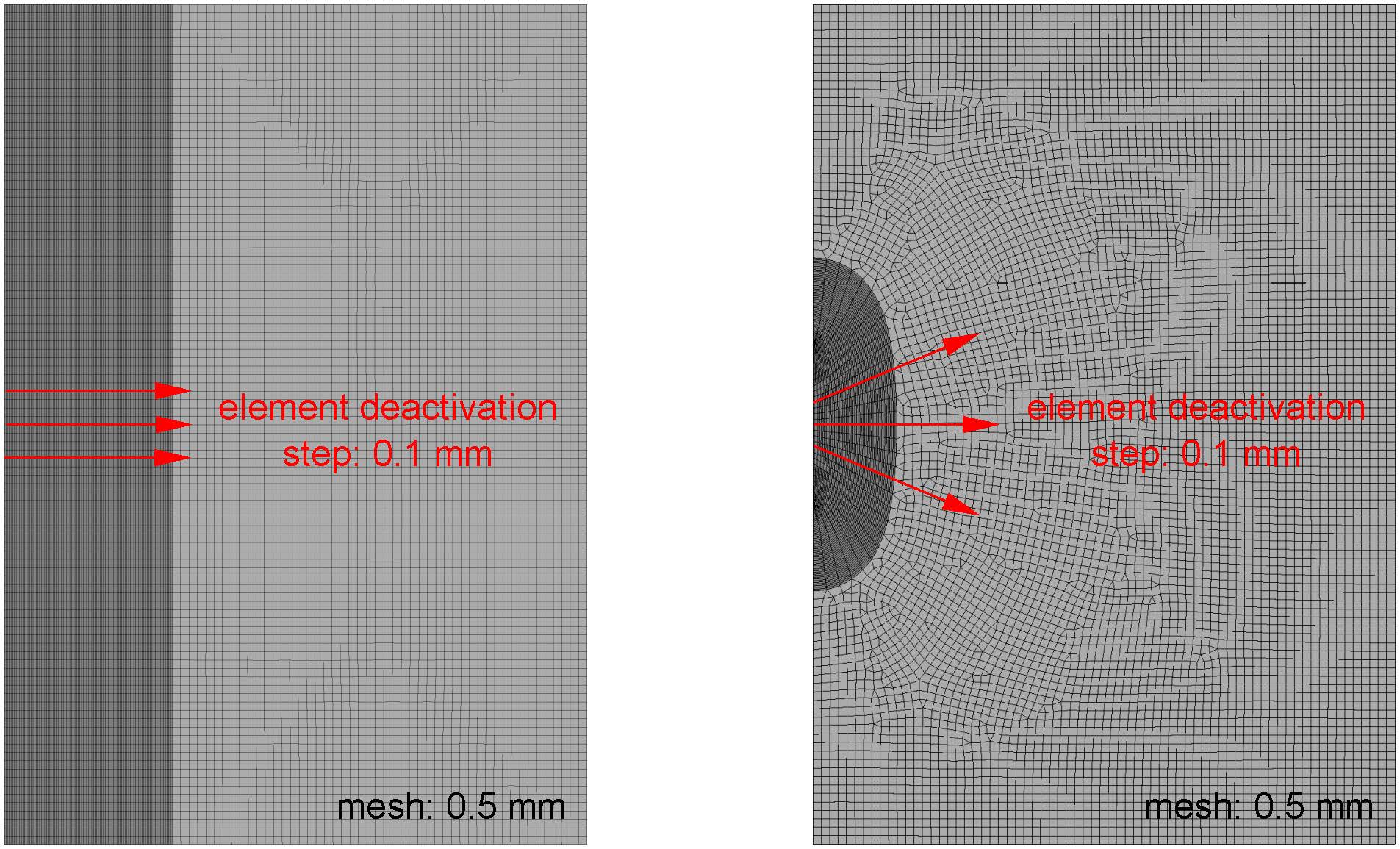

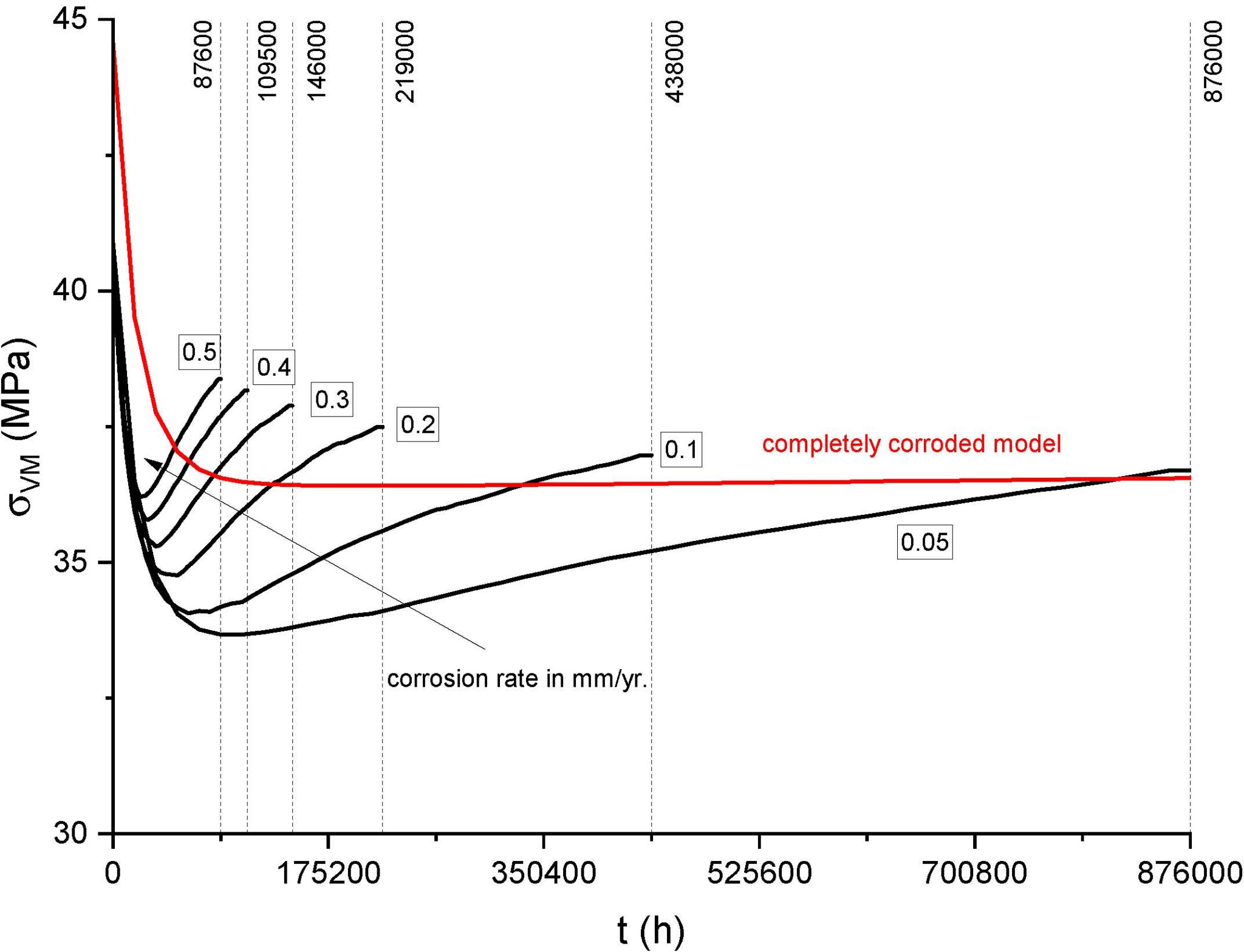

To answer this question FEA was used to analyze the progression of corrosion along with creep for both general and local metal loss in a straight section of pipe operated in the creep range (SA-335-P11, 10.4 MPa internal pressure, 528 °C). The simulation was run with different corrosion and creep rates in order to investigate the mutual effect of the two damage mechanisms.

How conservative is the assumption of fully-corroded model in a creep FEA?

Lorenzo Scano AuthorThe creep damage was calculated according to API 579-1 (Larson-Miller approach, minimum time-ro-rupture data) at every integration step with progressive corrosion and on a fully-corroded model for comparison:

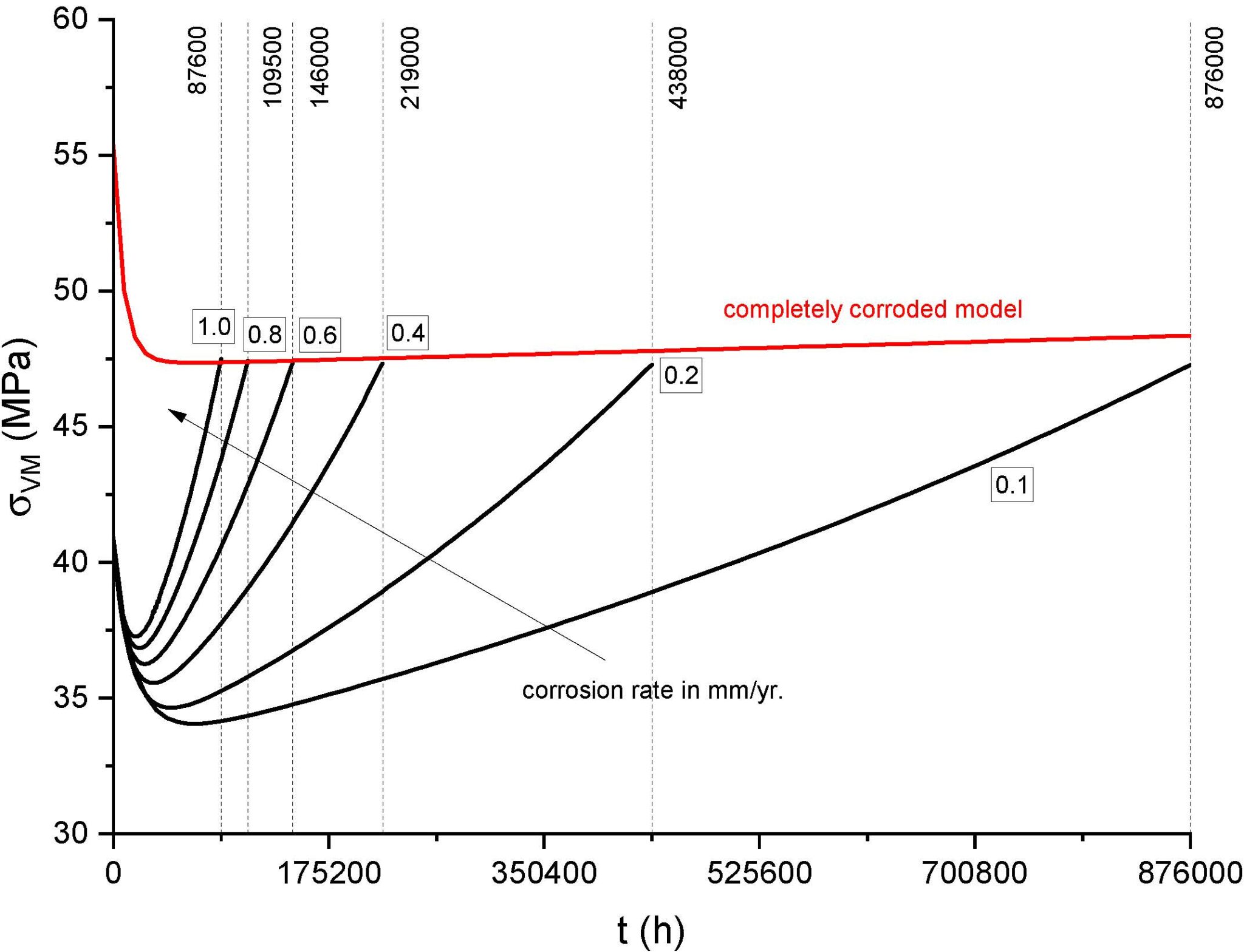

Stress relaxation plays a pivotal role in the analysis and is an antagonist mechanism of the metal loss. In the fully-corroded model there is an initial stress concentration due to the thickness loss and this will relax over time as long as creep progresses. On the other hande, the stresses will be lower at time-zero in the corroding model (no initial loss of thickness) and the metal loss will start competing with stress relaxation over time, as it can be seen on the following chart (general metal loss on the left and local metal loss on the right).

The analysis showed that the common approach of fully-corroded FEA has a margin of conservativism of 2.0 for general metal loss and 1.4 for local metal loss.

The answer is: 2 times for uniform corrosion and 1.4 times for localized corrosion

Lorenzo Scano AuthorThe paper is copyrighted by ASME and can be purchased here: