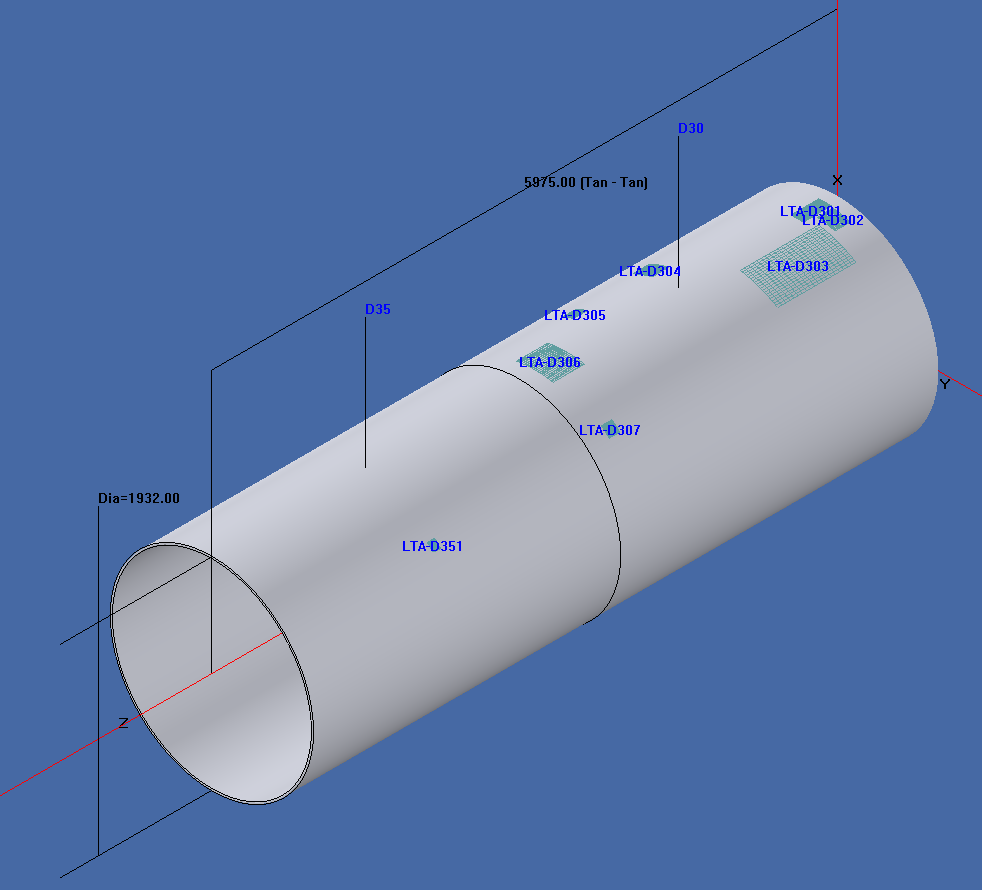

It is not uncommon to find pressure equipment fabricated decades ago but still well conserved and efficient in terms of fitness for service. This article presents the case-study of a pressure pipe serving a hydroelectric plant and manufactured during the 1940s. The pipe has a 2 m bore and is 390 m long with a net elevation of around 100 m. It was fabricated by hot-riveting of carbon-steel plates reinforced by standard-shape profiles. Studio Scano investigated its structural integrity and determined its residual life with respect to the metal loss induced, throughout the years, by the internal corrosion.

A widespread NDT campaign was the starting point of the structural assessment:

- Visual examination of the pipe surfaces

- Short-range guide-waves screening test

- Survey of pipe geometry to augment and support data from the original contruction drawings

- Point-thickness readings

- Depth measurements of local-thin areas (LTAs) via pit-gauge

More than 5000 PTRs were globally acquired and a corrosion rate could be established based on the previous NDTs, which dated back to 1985. Moreover, LTAs were also assessed geometrically and in terms of maximum depth to provide data for the FFS evaluation.

More than 5000 PTRs were acquired in order to determine a sound corrosion rate for the pressure pipe.

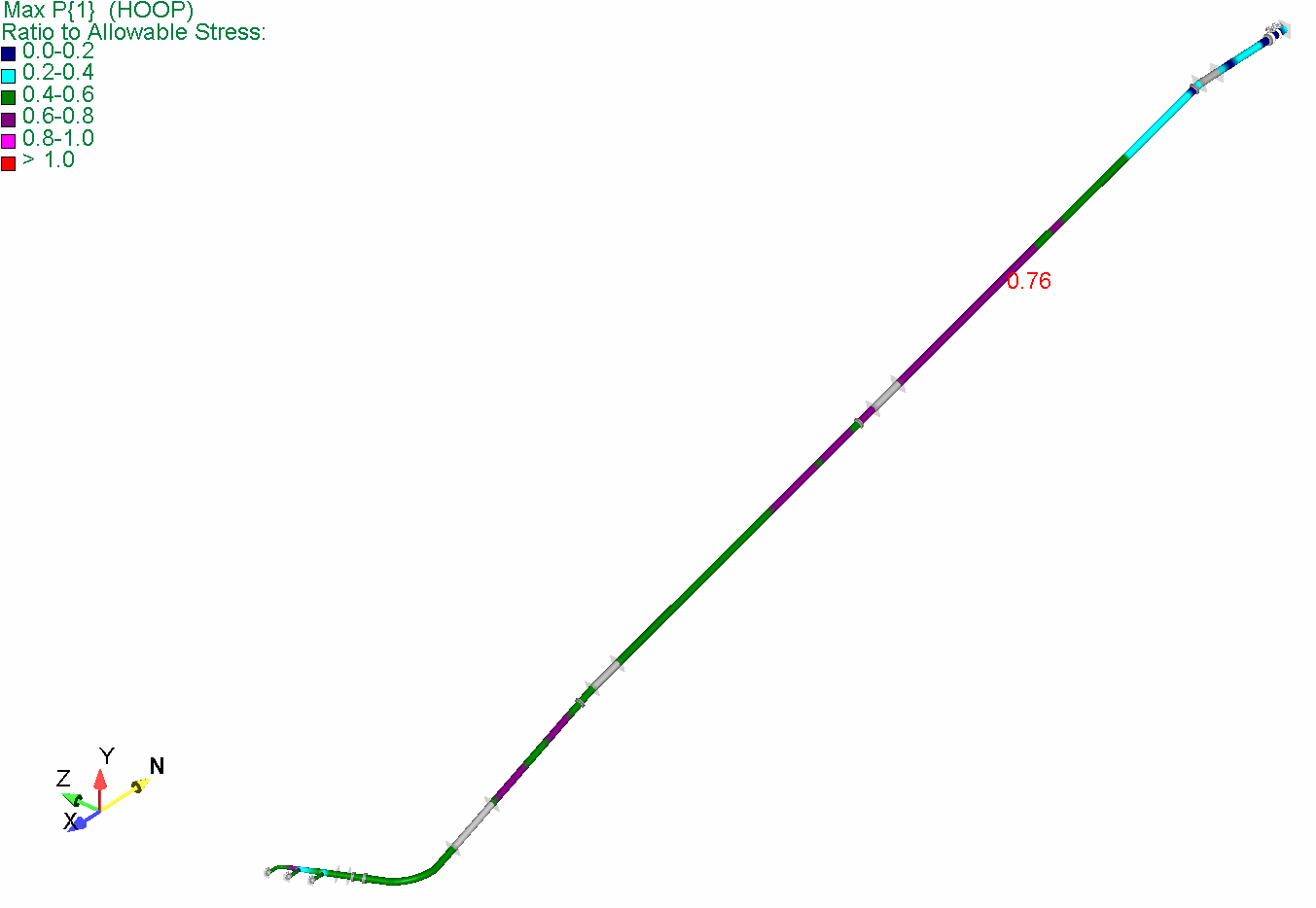

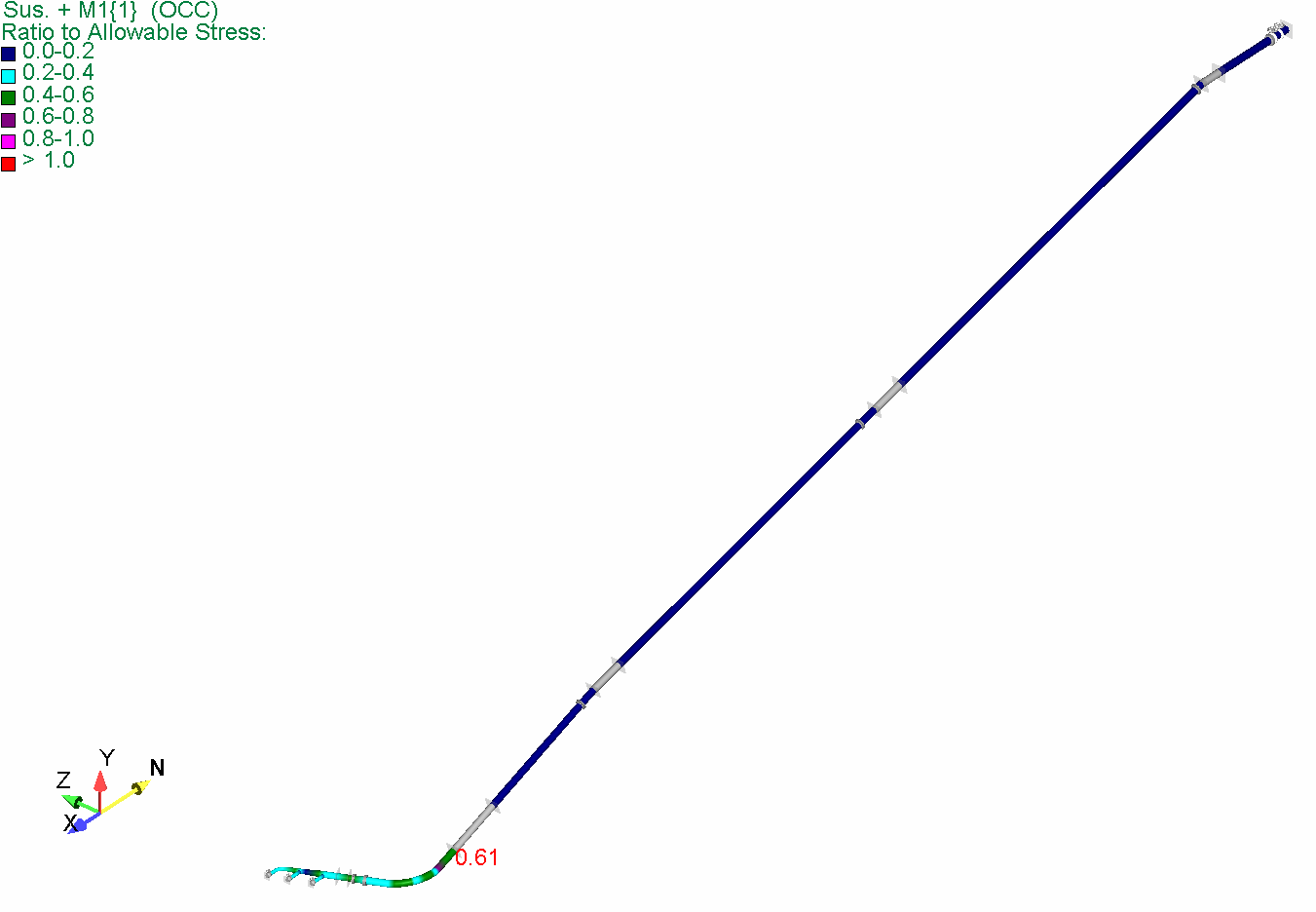

Studio ScanoThe FFS assessment was carried out according to Part 4 of API 579-1 via a Level 2 piping stress-analysis with Future Corrosion Allowance (FCA) at 10 years from the NDTs. The calculation determined the pressure hoop stresses and the longitudinal stresses induced by sustained, thermal and occasional loads. With respect to the latter, the water-hammer condition was deemed critical and thoroughly evaluated.

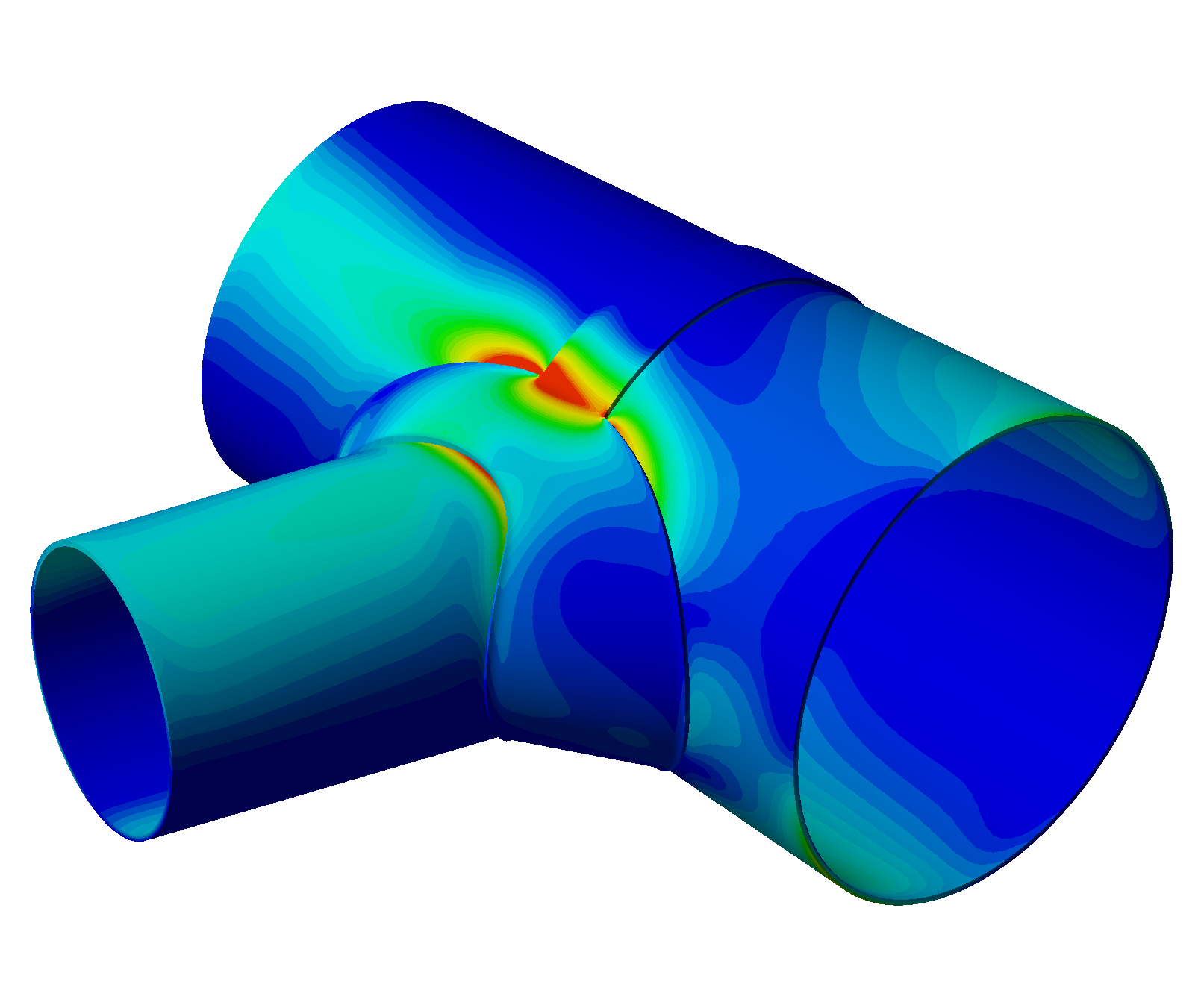

Furthermore, the pipe splits near the turbine inlets through fabricated, reinforced conical tees. These components are not standard and had to be assessed via FEA in order to calculate the Stress Intensification Factors to be used in the piping stress-analysis.

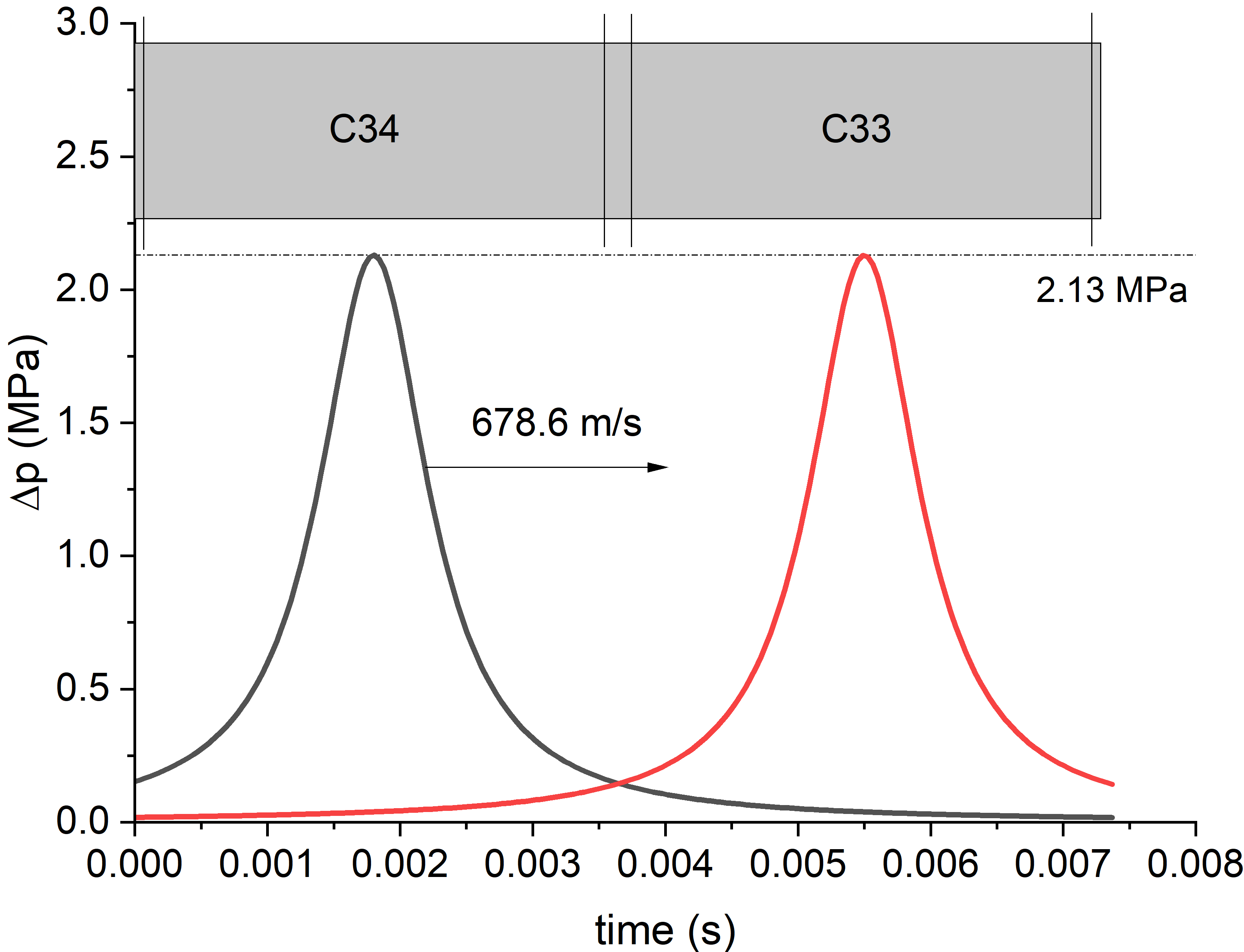

Piping stress-analysis was non-linear elastic for the evaluation of pressure, sustained and thermal stresses and transient dynamic for the calculation of the longitudinal stresses due to water-hammer. These were determined according to Jukowski’s theory based on the fluid velocity during down-stream valve closure and the speed of sound in the water. All the requirements were checked with FCA = 10 years and the contour-plots of the pressure hoop stresses and the water-hammer longitudinal stresses are reported herein.

A detailed, explicit-dynamics FEA was then carried out to thoroughly evaluate the stability of the most corroded pipe sections during water-hammer. The construction material was charaterized in terms of strain-hardening and a maximum equivalent-strain failure-criterion was imposed. The time-domain of the transient-dynamic analysis was set by the water-hammer pressure-wave traveling through these pipe sections.

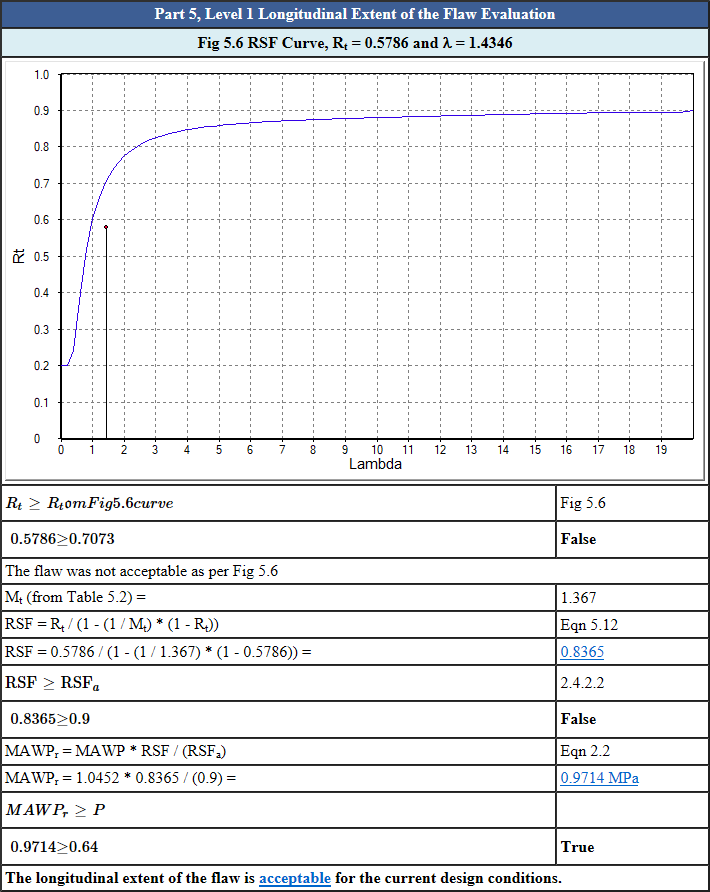

Finally, LTAs were checked according to API 579-1 Part 5 via Level 1/2 assessments. The residual life, based on the NDT-determined corrosion rate, was found considerably higher than 10 years.

Despite the pressure pipe age, the main conclusion of the FFS assessment was that it was fit for service with a 10 years future corrosion allowance.

Studio Scano