The impact of weld residual stresses on the structural integrity of pressure components is widely recognized in the FFS field. Annex 9D of API 579-1 2016 Ed. is dedicated to the topic along with 2015 WRC technical document “Development of Revised Weld Residual Stress Guidance for Fitness-For-Service Assessments in API 579-1/ASME FFS-1“.

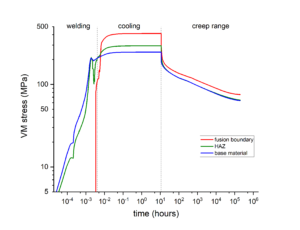

From a theoretical standpoint, the development of a stress gradient across a non-PWHT weld is detrimental to the component creep life. On the other hand, exposure in the creep range is supposed to relax the stresses in a reasonably short amount of time.

In the last two years, Studio Scano worked on a scientific research in collaboration with INAIL DIT in Rome, the Politecnico of Milan and the University of Bologna to shed light on this topic. Advanced FEA and weld simulation were carried out in order to investigate how the residual stresses impact on the API 579-1 creep residual life. Moreover, physical testing via X-ray spectrometry and hole-drilling strain gauge was conducted on a sample specimen coming from a high-energy piping (ASME SA-335-P22) operated in the creep regime for 200000 hours.

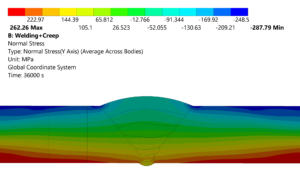

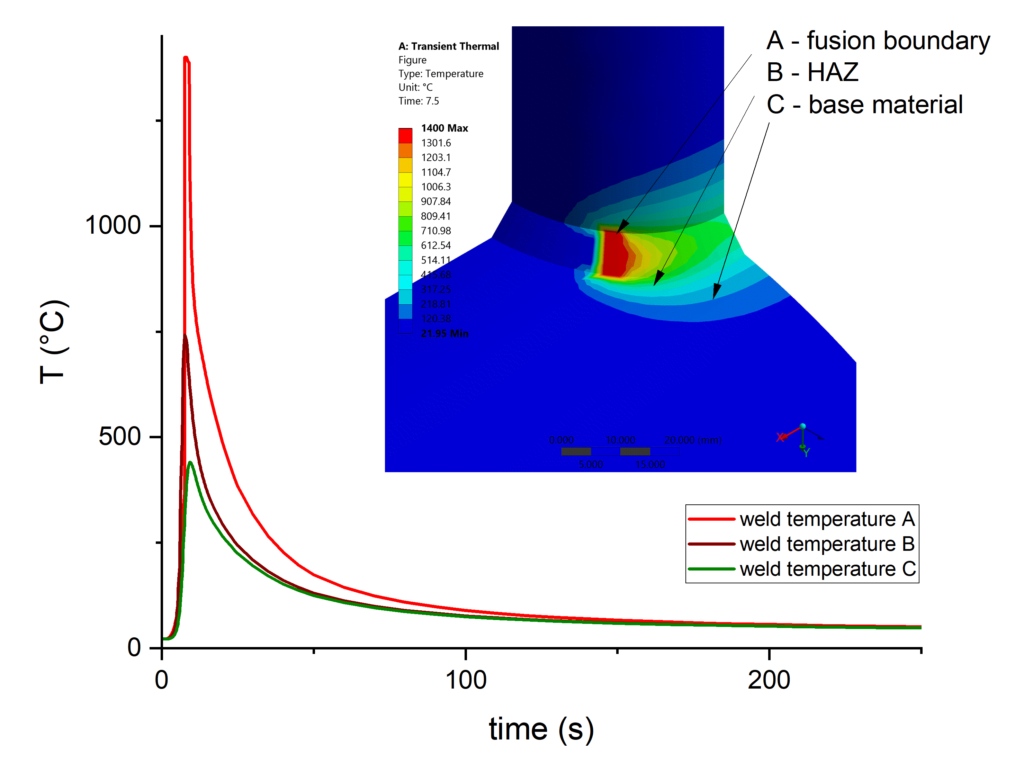

Both a butt-weld and a fabricated tee connection were investigated via FEA. The inelastic analysis simulated the welding process via element birth&death, the subsequent cooling down to RT, the operating pressure/temperature loading and the steady-state creep range up to 200000 hours. At every time-step, the creep damage was calculated according to API 579-1, thus including the whole stress history and relaxation.

The evaluation confirmed that the weld residual stresses do not alter the creep residual life in the long term, i.e., when the stress relaxation is complete, but they can actually shorten the time-to-rupture for short lives, i.e., for high initial stresses when the relaxation process has not completely flatten the peak stress level at weld.

Lorenzo Scano Leading authorThe research has been presented at the ASME PVP Conference over the last two years and it is copyrighted by ASME:

https://doi.org/10.1115/PVP2018-84662

https://doi.org/10.1115/PVP2019-93429

Moreover, the FEA results have been presented at the CAE Conference 2018 (presentation available here).